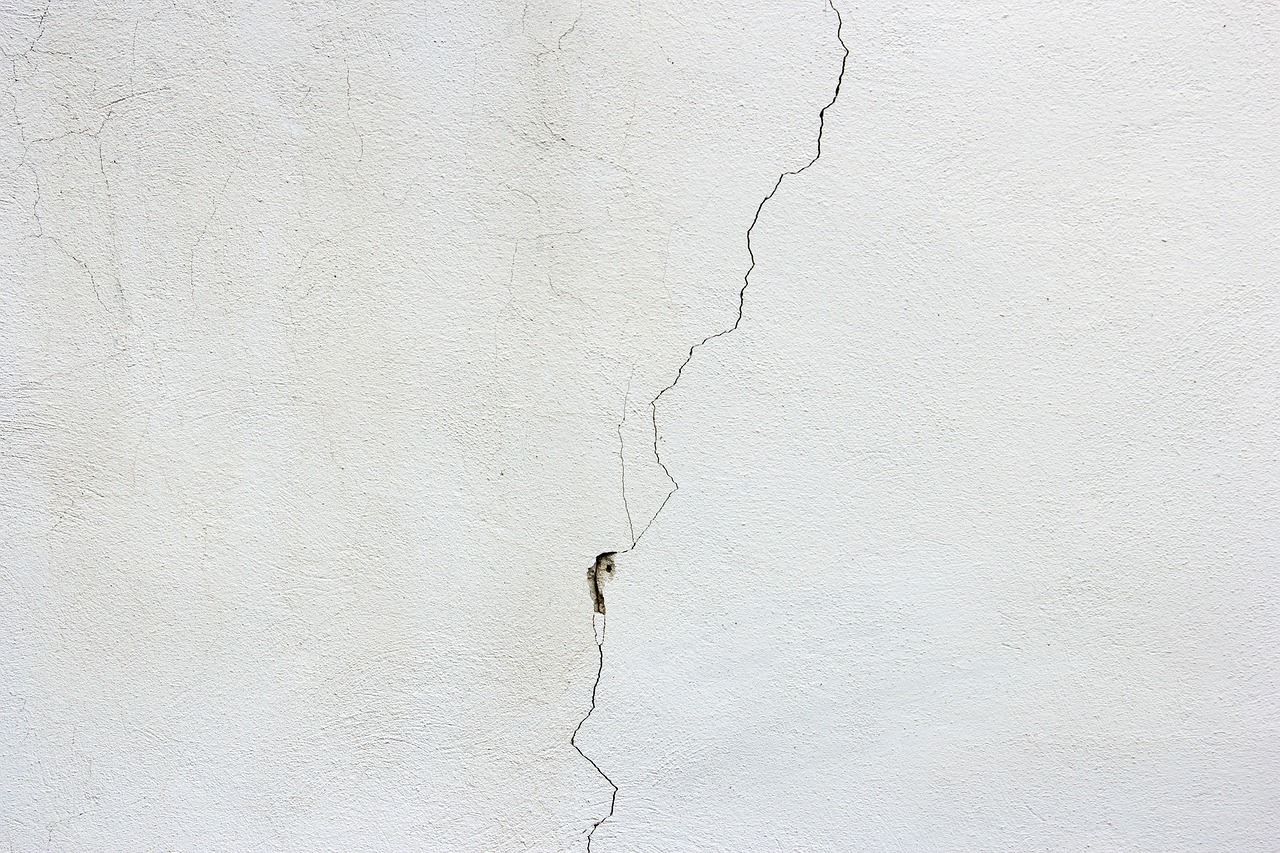

How Big of a Gap Can You Caulk?

Nov 7th 2023

In the world of construction and DIY home improvement, silicone sealants are invaluable. You can use them for sealing gaps and holes, preventing leaks, and enhancing the longevity of your structures. However, understanding the limitations of silicone in covering gaps without issues like collapse or shrinkage is crucial.

Understanding Silicone Types

Silicone sealants come in different formulations to suit a range of applications. Understanding these types is essential for effective gap coverage. The choice of sealant can significantly impact the outcome of your project.

For instance, acetoxy silicone emits a vinegar-like odor during curing. It is a common choice for general sealing purposes. Neutral cure silicone is better for places where fumes are a concern.

Additionally, you’ll find silicone sealants in various colors, allowing for seamless integration with your project’s aesthetics. Some types are designed for smooth surface adhesion, ensuring a secure bond on glass, metal, and similar materials.

In contrast, others are formulated to adhere to porous or rough surfaces more effectively. Selecting the appropriate silicone type is the first step in achieving optimal sealing results.

Maximum Gap Size for Silicone

Determining the maximum gap size that silicone sealant can effectively cover is a crucial aspect of successful sealing. While a small tube of silicone may seem like an ideal solution, be careful with the size of the gap you intend to seal.

Generally, silicone is most effective for small to medium-sized gaps, typically ranging from ⅛ inches to ½ inches. Attempting to seal large gaps with a single application may result in collapse or shrinkage. When facing wider gaps, epoxy-based sealants or specialized gap-filling products may be a better choice. Careful consideration of gap size ensures that your sealing project remains durable and effective.

Factors Influencing Silicone Performance

Several critical factors greatly influence the effectiveness of silicone sealants in covering gaps and holes. First, the condition of the surface is crucial. It must be clean and dry to ensure proper adhesion.

Environmental conditions also play a significant role. Temperature and humidity levels impact the silicone’s curing process. High-temp silicone sealants are designed for applications exposed to elevated temperatures. Room-temperature curing sealants are more versatile but require a longer curing time.

Professional advice and guidance can be helpful when dealing with complex sealing tasks. This is especially true when addressing high-temp applications or very large gaps. By carefully considering these factors, you can enhance the performance and durability of your silicone sealing project.

Tips and Tricks for Expanding Gap Coverage

To increase silicone sealant coverage for DIY projects, consider these helpful strategies. One of the go-to options is using a caulk gun, which ensures a more consistent application and allows for precise sealing. Consider RTV (Room-Temperature Vulcanizing) silicone, which is highly versatile and offers a professional finish.

For tasks involving extreme temperature variations, neutral cure silicone can be a wise choice. It doesn’t release acetic acid during curing, reducing corrosion risk and ensuring long-term durability. If you want to increase silicone coverage in wide gaps or holes, a filler material can help.

Mesh as a Gap Expander

When dealing with especially large gaps, traditional silicone sealants may fall short of your needs. In such cases, consider using mesh to expand the coverage effectively. You can find mesh materials designed for this purpose in consumer products stores or specialized heat-resistant options. This method is particularly advantageous when working with gaps that require more structural support, such as those in building or automotive applications.

Using mesh allows the silicone to bond securely with the surrounding surfaces, offering a resilient and long-lasting seal. In addition to bridging large gaps, mesh provides extra reinforcement, making it an ideal solution for projects where durability and heat resistance are critical.

Silicone Polymer and Silicone Rubber

Understanding the characteristics of silicone materials is vital for making informed decisions in sealing large gaps. Silicone is available in different forms, including silicone polymer and silicone rubber. Silicone rubber, known for its flexibility and durability, is commonly used for sealing purposes, while silicone polymers are versatile and can offer a broader range of applications.

RTV silicone rubber is a great choice for many sealing tasks. It cures at ambient temperatures and provides both flexibility and durability. Depending on the specific project requirements, you may choose between silicone polymer and silicone rubber. What you choose can significantly impact the outcome of your project.

Conclusion

Mastering the art of silicone sealing for covering gaps and holes involves carefully selecting silicone types, understanding their limitations, and applying effective techniques. The choice of silicone type, the consideration of gap size, and adherence to environmental factors are essential for successful sealing.

Whether you’re a DIY enthusiast or a professional, these insights will help you achieve durable and effective results. By being mindful of your materials, methods, and strategies, you can confidently tackle any gap! Using premium products from Silicone Depot, you can tackle gap-sealing projects with the assurance of a job well done.